Riddle solved: Why was Roman concrete so durable?

The ancient Romans were masters of engineering, constructing vast networks of roads, aqueducts, ports, and massive buildings, whose remains have survived for two millennia. Many of these structures were built with concrete: Rome’s famed Pantheon, which has the world’s largest unreinforced concrete dome and was dedicated in A.D. 128, is still intact, and some ancient Roman aqueducts still deliver water to Rome today. Meanwhile, many modern concrete structures have crumbled after a few decades.

古罗马人是工程大师,他们建造了庞大的道路网络、引水渠、港口和大型建筑,这些遗迹已经存在了两千年。其中许多建筑都是用混凝土建造的:罗马著名的万神殿拥有世界上最大的无钢筋混凝土圆顶,于公元128年落成,至今仍完好无损,一些古罗马的引水渠至今仍在向罗马供水。与此同时,许多现代混凝土结构在几十年后就倒塌了。

Researchers have spent decades trying to figure out the secret of this ultradurable ancient construction material, particularly in structures that endured especially harsh conditions, such as docks, sewers, and seawalls, or those constructed in seismically active locations.

研究人员花了几十年的时间试图找出这种超级耐用的古代建筑材料的秘密,特别是在承受特别恶劣条件的结构中,如码头、下水道和海堤,或那些建造在地震活跃地区的结构。

Now, a team of investigators from MIT, Harvard University, and laboratories in Italy and Switzerland, has made progress in this field, discovering ancient concrete-manufacturing strategies that incorporated several key self-healing functionalities. The findings are published in the journal Science Advances, in a paper by MIT professor of civil and environmental engineering Admir Masic, former doctoral student Linda Seymour, and four others.

现在,来自麻省理工学院、哈佛大学以及意大利和瑞士实验室的一组研究人员在这一领域取得了进展,他们发现了古老的混凝土制造策略,其中包含了几种关键的自我修复功能。研究结果发表在《科学进展》杂志上,由麻省理工学院土木与环境工程教授阿米尔·马西克、前博士生琳达·西摩和其他四人共同撰写。

For many years, researchers have assumed that the key to the ancient concrete’s durability was based on one ingredient: pozzolanic material such as volcanic ash from the area of Pozzuoli, on the Bay of Naples. This specific kind of ash was even shipped all across the vast Roman empire to be used in construction, and was described as a key ingredient for concrete in accounts by architects and historians at the time.

多年来,研究人员一直认为,古代混凝土耐久性的关键是基于一种成分:火山灰材料,比如来自那不勒斯湾波佐利地区的火山灰。这种特殊的灰烬甚至被运往整个罗马帝国用于建筑,在当时的建筑师和历史学家的描述中,它被描述为混凝土的关键成分。

Under closer examination, these ancient samples also contain small, distinctive, millimeter-scale bright white mineral features, which have been long recognized as a ubiquitous component of Roman concretes. These white chunks, often referred to as “lime clasts,” originate from lime, another key component of the ancient concrete mix. “Ever since I first began working with ancient Roman concrete, I’ve always been fascinated by these features,” says Masic. “These are not found in modern concrete formulations, so why are they present in these ancient materials?”

经过仔细检查,这些古老的样品还含有微小的、独特的、毫米级的亮白色矿物特征,这些特征长期以来一直被认为是罗马混凝土的普遍组成部分。这些白色的大块,通常被称为“石灰碎屑”,来自石灰,古代混凝土混合物的另一个关键成分。“自从我第一次开始使用古罗马混凝土,我就一直被这些特征迷住了,”马西克说。“在现代混凝土配方中没有发现它们,那么为什么它们会出现在这些古老的材料中呢?”

Previously disregarded as merely evidence of sloppy mixing practices, or poor-quality raw materials, the new study suggests that these tiny lime clasts gave the concrete a previously unrecognized self-healing capability. “The idea that the presence of these lime clasts was simply attributed to low quality control always bothered me,” says Masic. “If the Romans put so much effort into making an outstanding construction material, following all of the detailed recipes that had been optimized over the course of many centuries, why would they put so little effort into ensuring the production of a well-mixed final product? There has to be more to this story.”

以前被忽视的仅仅是草率的搅拌实践或劣质原材料的证据,新的研究表明,这些微小的石灰碎屑赋予了混凝土以前未被认识到的自我修复能力。马西克说:“这些石灰碎屑的存在仅仅是因为质量控制不佳,这种想法一直困扰着我。”“如果罗马人在制造一种优秀的建筑材料上投入了如此多的精力,遵循了经过许多世纪优化的所有详细配方,为什么他们在确保生产出混合良好的最终产品上投入的精力如此之少呢?”这个故事肯定不止这些。”

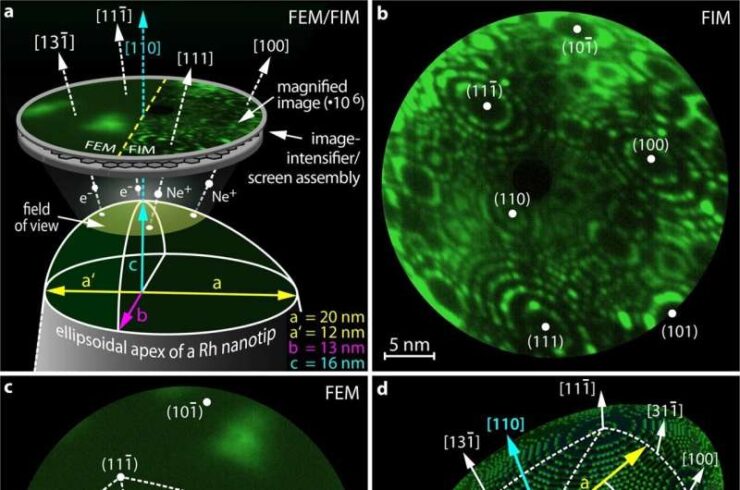

Upon further characterization of these lime clasts, using high-resolution multiscale imaging and chemical mapping techniques pioneered in Masic’s research lab, the researchers gained new insights into the potential functionality of these lime clasts.

通过使用Masic研究实验室开创的高分辨率多尺度成像和化学制图技术,对这些石灰碎屑进行进一步表征,研究人员对这些石灰碎屑的潜在功能有了新的认识。

Historically, it had been assumed that when lime was incorporated into Roman concrete, it was first combined with water to form a highly reactive paste-like material, in a process known as slaking. But this process alone could not account for the presence of the lime clasts. Masic wondered: “Was it possible that the Romans might have actually directly used lime in its more reactive form, known as quicklime?”

历史上,人们一直认为,当石灰被加入罗马混凝土中时,它首先与水结合,形成一种高活性的糊状材料,这个过程被称为熟化。但仅凭这一过程并不能解释石灰碎屑的存在。Masic想知道:“有没有可能罗马人实际上直接使用了更活跃的石灰形式,即生石灰?”

Studying samples of this ancient concrete, he and his team determined that the white inclusions were, indeed, made out of various forms of calcium carbonate. And spectroscopic examination provided clues that these had been formed at extreme temperatures, as would be expected from the exothermic reaction produced by using quicklime instead of, or in addition to, the slaked lime in the mixture. Hot mixing, the team has now concluded, was actually the key to the super-durable nature.

通过研究这种古老混凝土的样本,他和他的团队确定,这些白色夹杂物确实是由各种形式的碳酸钙组成的。光谱检查提供了线索,表明这些物质是在极端温度下形成的,正如人们所期望的那样,这些物质是在混合物中使用生石灰而不是熟石灰或与熟石灰一起产生的放热反应中形成的。研究小组现在得出结论,热混合实际上是这种材料超级耐用的关键。

“The benefits of hot mixing are twofold,” Masic says. “First, when the overall concrete is heated to high temperatures, it allows chemistries that are not possible if you only used slaked lime, producing high-temperature-associated compounds that would not otherwise form. Second, this increased temperature significantly reduces curing and setting times since all the reactions are accelerated, allowing for much faster construction.”

“热混合的好处是双重的,”Masic说。“首先,当整个混凝土被加热到高温时,它可以产生仅使用熟石灰时不可能产生的化学物质,从而产生不会形成的高温相关化合物。其次,温度的升高显著减少了固化和凝固时间,因为所有的反应都加速了,可以更快地施工。”

During the hot mixing process, the lime clasts develop a characteristically brittle nanoparticulate architecture, creating an easily fractured and reactive calcium source, which, as the team proposed, could provide a critical self-healing functionality. As soon as tiny cracks start to form within the concrete, they can preferentially travel through the high-surface-area lime clasts. This material can then react with water, creating a calcium-saturated solution, which can recrystallize as calcium carbonate and quickly fill the crack, or react with pozzolanic materials to further strengthen the composite material. These reactions take place spontaneously and therefore automatically heal the cracks before they spread. Previous support for this hypothesis was found through the examination of other Roman concrete samples that exhibited calcite-filled cracks.

在热混合过程中,石灰碎屑形成了一种典型的脆性纳米颗粒结构,形成了一种容易断裂的活性钙源,正如研究团队所提出的,这可以提供关键的自我修复功能。一旦混凝土内部开始形成微小的裂缝,它们就会优先穿过高表面积的石灰碎屑。然后,这种材料可以与水反应,产生饱和钙溶液,该溶液可以再结晶为碳酸钙并快速填充裂缝,或者与火山灰材料反应,进一步增强复合材料。这些反应是自发发生的,因此会在裂缝扩散之前自动愈合。之前对这一假设的支持是通过检查其他表现出方解石填充裂缝的罗马混凝土样本发现的。

To prove that this was indeed the mechanism responsible for the durability of the Roman concrete, the team produced samples of hot-mixed concrete that incorporated both ancient and modern formulations, deliberately cracked them, and then ran water through the cracks. Sure enough: Within two weeks the cracks had completely healed and the water could no longer flow. An identical chunk of concrete made without quicklime never healed, and the water just kept flowing through the sample. As a result of these successful tests, the team is working to commercialize this modified cement material.

为了证明这确实是导致罗马混凝土耐久性的机制,研究小组制作了混合了古代和现代配方的热拌混凝土样品,故意将其开裂,然后让水从裂缝中流过。果然,不到两周,裂缝就完全愈合了,水再也流不出去了。同样一块没有生石灰的混凝土永远不会愈合,水一直在样品中流动。由于这些成功的测试,该团队正在努力将这种改性水泥材料商业化。

“It’s exciting to think about how these more durable concrete formulations could expand not only the service life of these materials, but also how it could improve the durability of 3D-printed concrete formulations,” says Masic.

Masic说:“想到这些更耐用的混凝土配方不仅可以延长这些材料的使用寿命,而且还可以提高3d打印混凝土配方的耐久性,这是令人兴奋的。”

Through the extended functional lifespan and the development of lighter-weight concrete forms, he hopes that these efforts could help reduce the environmental impact of cement production, which currently accounts for about 8 percent of global greenhouse gas emissions. Along with other new formulations, such as concrete that can actually absorb carbon dioxide from the air, another current research focus of the Masic lab, these improvements could help to reduce concrete’s global climate impact.

通过延长功能寿命和开发更轻重量的混凝土形式,他希望这些努力可以帮助减少水泥生产对环境的影响,目前水泥生产占全球温室气体排放的8%左右。与其他新配方一起,比如可以从空气中吸收二氧化碳的混凝土,这是Masic实验室目前的另一个研究重点,这些改进可以帮助减少混凝土对全球气候的影响。

The research team included Janille Maragh at MIT, Paolo Sabatini at DMAT in Italy, Michel Di Tommaso at the Instituto Meccanica dei Materiali, in Switzerland, and James Weaver at the Wyss Institute for Biologically Inspired Engineering at Harvard University. The work was carried out with the assistance of the archeological museum of Priverno, Italy.

该研究小组包括麻省理工学院的Janille Maragh,意大利DMAT的Paolo Sabatini,瑞士Meccanica dei Materiali研究所的Michel Di Tommaso和哈佛大学Wyss生物工程研究所的James Weaver。这项工作是在意大利普里韦诺考古博物馆的协助下进行的。

Read more at ScienceDaily.com

在ScienceDaily.com上阅读更多